In the world of commercial and industrial painting, the precision of results and efficiency are two paramount factors. Optimal results in the shortest possible time are the key concern of professional painters and contractors in the industry. When the industry is flooded with ways, up gradation of your Binks paint sprayer parts is one of the easiest ways to achieve the desired results. Binks is a trusted and renowned name in the painting industry. From offering high-quality products to giving quality upgrades to these parts, Binks can elevate your painting experience.

Binks has a proud reputation when it comes to quality and performance. However, as with all the equipment, there is always room for upgradation. And by optimizing several parts of the sprayer, you can boost the performance of your paint sprayer.

This blog will explore the importance of optimization of your paint sprayers with genuine parts to upgrade their efficiency and superior performance.

Why Upgrade your Binks Sprayer Parts

Binks sprayer parts are standard in many circles of professional painting. But wear and tear can take a toll on all the machines. Upgraded machines can often surpass the performance of their original parts. Therefore, upgrading the parts of your paint sprayers is a great way to achieve optimal efficiency.

Here’s why you should consider upgrading parts of your paint sprayers,

Enhanced Performance

Take this as updating the ‘software’ of your computer or mobile. The operation becomes smooth. The same goes for upgrading the parts of your sprayers, you can unlock smooth operation. Moreover, faceless clogging, and enjoy consistent and uniform spraying patterns.

Increased Longevity

While many paint sprayers are built to last, Binks paint sprayer parts can enhance the performance, as well as, extend the longevity of the machine.

Increased Efficiency

Efficiency is the cornerstone of any professional painting project. Upgrading parts like the air compressor and the fluid delivery system can bring drastic changes to the efficiency of your projects.

Time-Saving

Time is money, and contractors and professional painters live by it. In industrial painting projects, where large-scale painting is a norm, even the slightest increase in efficiency can translate into significant time-saving.

Versatility

Commercial and industrial painting projects are not limited to just any specification. Different projects have different areas of work and specs. Upgrading your part sprayers to premium parts, allow you to adapt to the requirements of different project.

Whether working with different projects, or with different viscosities of paint, having flexible parts that allow you to switch out definitely streamlines your experience.

Cost Efficiency

By upgrading the parts of your paint sprayers, you can eliminate the need for frequent repairs and replacements. New parts also reduce the need for repeated maintenance of your sprayers.

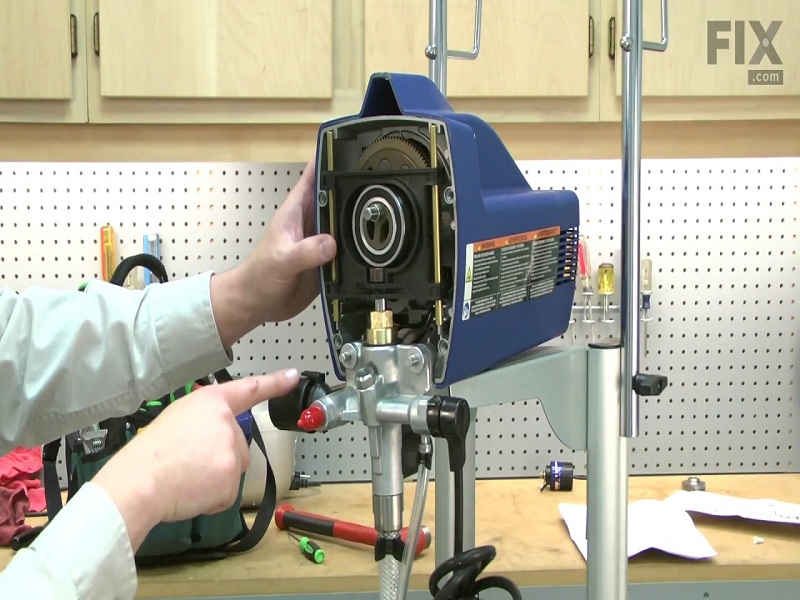

Key Parts to Consider Upgrading with Binks Sprayer Parts

Nozzles and Tips

Nozzles and tips have a direct influence on the spraying pattern and the final finish of your paint sprayer. Upgrading to precision-engineered nozzles, you can achieve consistent coverage, and reduce overspray. Reduced overspray saves you from extra material costs.

Hoses

The quality of the hose has a direct impact on how smoothly the paint flows from the container to the nozzle of your sprayer gun. When upgraded every now and then, they resist kinking and show resistance to wear and tear and premature damage to your sprayer.

Filters

Filters participate in the consistent application of paint by preventing unwanted particles to taint the paint. Optimization of the filters with Binks parts can reduce clogging while giving optimal efficiency.

O-rings and Seals

Seals and O-rings are small parts of your sprayers but are equally essential in maintaining a smooth painting journey. They make sure that your paint sprayers remain leakage free. Upgrading your seals and O-rings with premium materials can offer optimal resistance to paint and solvent materials.

Tips for Optimization Process

Know your Model

Always ensure that the Binks parts you are purchasing show optimal compatibility with your specific model of paint sprayer.

Professional Installation

While most of the upgrades can be DIY, you can always seek professional help for the installation of the parts. Paint sprayers are hefty investments; you cannot try out things on them. If you’ve not got it under control, it’s better to seek professional help.

Prioritize

When on budget, identify which upgrades are the need of the hour. The upgrades that deliver the most immediate results can always be your priority, as they’ll directly enhance your performance.

Conclusion

Upgrading your Binks sprayer parts can be your strategic move to yield optimal efficiency as well as substantial benefits for your painting operations. Enhanced performance, versatility, increased efficiency, time-saving, and cost savings are the few benefits that upgrading offers. By focusing on key components of your sprayers like nozzles, hoses, seals and O-rings, and filters, you can uplift the efficiency of your painting projects. Embrace the culture of continuous improvement and efficiency, starting with the very tools that represent the backbone of your painting projects.