Graco paint sprayers are globally recognized for their reliability, high-quality performance, and efficiency. Paint sprayers produced by Graco have revolutionized the painting industry bringing proficiency and making the projects faster. Graco offers one of the most professional tools for painting projects. But like any mechanical device, Graco sprayers require proper maintenance for proper functioning. You may bring your machines to Graco paint sprayer repair centers once in a while to ensure regular checkups.

Maintenance of a paint sprayer plays a significant role in increasing the longevity of the machine. Regular visits to Graco paint sprayer repair center, to look for wear and tears is critically important to protect your machine from further damage.

In this blog, we will explore the tips and tricks to maintain your Graco spraying machines. A well-maintained machine not only has a longer lifespan but keeps functioning smoothly and efficiently. Furthermore, this blog will walk you through the essential tips to upgrade as well as preserve the performance of your paint sprayer.

Cleaning is Crucial

The very first step in maintaining your Graco sprayer is cleaning, and it’s clearly the most crucial. The cleaning process removes dirt, debris, and paint residues that may clog the inner parts of your paint sprayer.

Cleaning should be conducted after every use, yes, it is that crucial. On every cleaning venture, make sure you pay close attention to the nozzles, tips, filters, and gun of your sprayer. Neglecting this step can lead to clogging of hoses, nozzles, and other components causing poor performance that may even lead to device failure.

- To clean your Graco paint sprayers effectively;

- Drain by disconnecting the paint supply, relieving pressure in the sprayer.

- Remove all the removable parts like guards, tips, and nozzles to rinse them thoroughly with water.

- Flush all the components of the sprayer with a suitable cleaning solution to get rid of paint residues in the system.

- Clean the gun filter by dissembling it to free it from dirt and debris.

Regular Lubrication

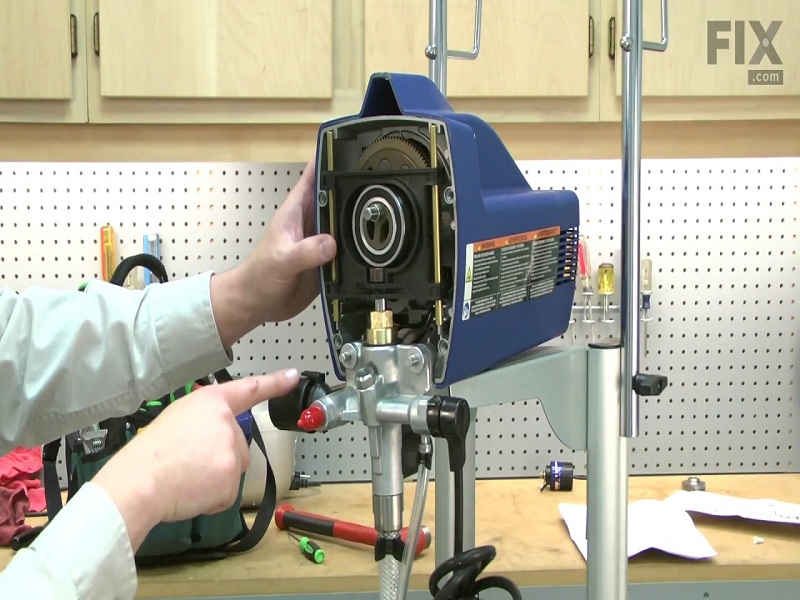

The friction produced in the moving parts leads to premature wear and tear of those parts. Keeping your Graco paint sprayer well-lubricated is an essential part of the maintenance routine to ensure friction-free movement of the movable components.

You can use Graco Throat Seal Liquid (TSL) or a suitable dupe, to lubricate the valve, piston rod, and other crucial components. Frequent lubrication of the critical parts also prevents the paint from drying in any of the internal parts.

Keep the Filters Clean

Filters play a significant role in a smooth and consistent paint application on your desired surfaces. They prevent dirt and debris from clogging, resulting in a smooth emission of paint particles from the sprayer. Keeping the filter clean, is, therefore, significantly important in maintaining the high-quality performance of your sprayer.

Regularly inspect your filters, to clean them efficiently. Also, replace them once in a while to ensure smooth application of paint. Consider replacing your filters if you see signs of wear and tear. You can easily replace the filters at home by following the manufacturer’s guide or you can bring your sprayer to a Graco paint sprayer repair center.

Check Seals and O-rings

Over time, O-rings and seals wear out, leading to decreased performance from leakages. Regular inspection of seals and O-rings is, therefore, an important step in the maintenance routine of your sprayer.

Regular inspections help you rule out wear and tear in the early stages of damage to prevent further problems. Faulty components should promptly be replaced after seeing the signs of damage. Lubrication of seals and O-rings prior to installation is important.

System Pressure Check

Pressure plays an important role in the proper functioning of your Graco paint sprayers. So, system pressure checks are crucial for the optimal functioning of your paint sprayers. Fluctuations in the spraying pressure and inconsistent spray patterns are indicators of problems in the systems’ pressure settings.

Inconsistent spraying patterns lead to textured finishes, which you may not want. Therefore, issues in pressure settings should be addressed immediately to ensure the proper functioning of your Graco sprayers. Refer to the user instructions given in the user manual to address issues regarding pressure adjustments.

Storage of Your Graco Sprayers

Proper storage of your machine is as important as its maintenance. When not in use, store your paint sprayers in a dry, cool space away from direct sunlight. If you plan to store your sprayer for a longer period, flush your sprayer with an antifreeze or pump protector solution. These solutions will prevent the drying out of residual paints in various components of your sprayer.

Conclusion

Graco paint sprayers are valuable tools. They require both your time and attention to deliver high-quality results and consistent performance. By following the essential tips, you can not only add to the lifespan of your machine but reduce downtime. Moreover, you will achieve excellent painting outcomes with consistent finish and superior results in every project.

Remember to read the instructions given by the manufacturer to incorporate them in your learning and maintenance practices. You can easily master the art of painting using these tips!