Shopping cart

Your Cart is empty

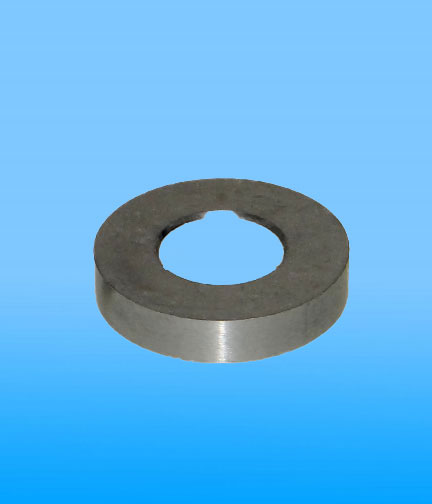

Titan 762-137 Intake Valve Seat - Aftermarket | Bedford 58-2437

PriceQuantity

762-137

MPN:58-2437

Manufacturer:Bedford Precision Parts

Guaranteed safe & secure checkout

Titan 762-137 Intake Valve Seat - Premium Aftermarket Replacement for Airless Sprayer Pump Inlet Valve | Bedford 58-2437

The Bedford 58-2437 is a premium aftermarket replacement for the Titan 762-137 intake valve seat, a critical wear component that forms the sealing surface for the inlet ball check within the pump manifold. This precision-machined part ensures proper fluid priming and prevents pressure loss, restoring OEM-level performance and reliability to your sprayer with significant cost savings.

Why Choose This Intake Valve Seat

- Precision-machined to exact OEM specifications for perfect ball seal

- Forms the critical sealing surface for the inlet check valve function

- Cost-effective aftermarket solution for pump manifold repair and rebuilds

- Restores proper pump priming and prevents fluid backflow and pressure loss

Compatibility Products

- Titan Pump Manifold Assemblies (Part #762-137)

- Pump Rebuild Kits specifying intake valve seat 762-137

- Machines using Titan intake valve seat #762-137

- Manifolds designed for this specific inlet valve seat component

Compatible with Titan airless spray pumps specifying OEM part number 762-137.

What It Fits

- Titan Pump Manifolds (Model-specific, uses 762-137)

- Inlet Valve Assemblies designed for seat #762-137

- Equipment requiring Titan OEM part number 762-137

- Manifold bores that accept this specific valve seat configuration

If your pump rebuild kit or manifold parts list specifies Titan 762-137, Bedford 58-2437 is the correct aftermarket replacement.

Technical Specifications

| Aftermarket Part # | Bedford 58-2437 |

|---|---|

| OEM Part # | Titan 762-137 |

| Component Type | Intake Valve Seat |

| Function | Sealing Surface for Inlet Ball Check |

| Kit Compatibility | Titan Pump Rebuild Kits (762-137) |

| Condition | New Aftermarket |

| Application | Pump Manifold Inlet Valve Assembly |

| Brand | Bedford Precision Parts (Aftermarket) |

Installation Notes

- Disassemble pump manifold to access the inlet valve chamber

- Remove old seat and thoroughly clean the seating bore in the manifold

- Press or tap new seat squarely into the bore until fully seated

- Always install a new inlet ball check (e.g., 805-204) and spring against the new seat

- Reassemble manifold, ensuring all seals are replaced, and test pump for proper priming

Pro Tip: The valve seat and ball check are a matched wear pair. Always replace both simultaneously for a reliable seal. Inspect the valve pusher for wear as well.

When to Replace the Valve Seat

- Pump fails to prime or loses prime frequently

- Visible wear, scoring, or erosion on the seat's sealing surface

- During any pump manifold overhaul or complete rebuild

- If the inlet ball check is being replaced due to wear or damage

Bedford vs OEM

| Feature | Bedford Aftermarket | OEM (Titan) |

|---|---|---|

| Fit & Function | Direct replacement for 762-137 | Original factory component |

| Precision | Machined to exact tolerances for proper ball check sealing | Original equipment specifications |

| Durability | Manufactured from wear-resistant materials for long service life | Factory material specification |

| Value | Significant cost savings for a critical wear component | Higher cost for brand name part |