Why Choose This Hose Assembly

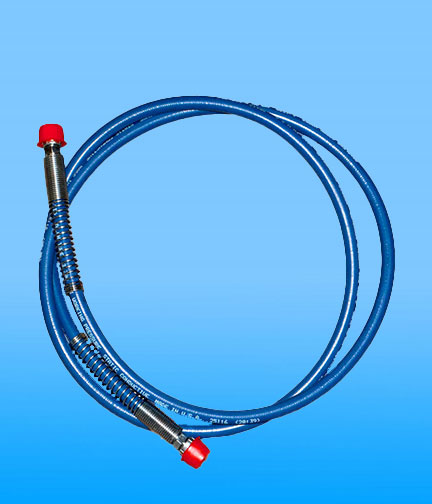

- Optimized 7′ length helps maintain pressure and pattern consistency near the spray gun.

- Crimped 1/4" hose with threaded ends installs quickly for reduced downtime.

- Built for walk-behind roadway and parking-lot striping environments.

Color: Black hose with metallic crimped fittings for clear on-rig visibility.