Shopping cart

Your Cart is empty

Graco 166026 Piston Seal - Aftermarket | Bedford 6-511

PriceQuantity

166026

MPN:6-511

Manufacturer:Bedford Precision Parts

Guaranteed safe & secure checkout

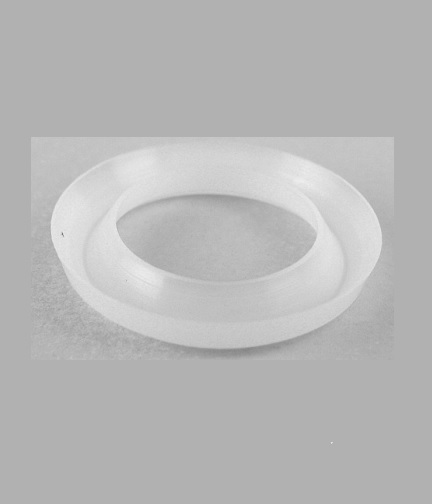

Graco 166026 Piston Seal - Aftermarket Replacement | Bedford 6-511

The Bedford 6-511 provides a precision-engineered piston seal designed as a direct aftermarket replacement for Graco 166026. This critical pump component ensures effective fluid displacement and pressure generation within airless sprayer systems, maintaining optimal performance and consistent material delivery. Manufactured from durable sealing materials, this piston seal maintains its flexibility and sealing characteristics under normal operating pressures and temperature variations. The precise dimensional specifications and consistent material quality deliver reliable service life, offering maintenance technicians a cost-effective solution for restoring proper pump function and pressure performance to their Graco equipment during service and maintenance procedures.

Why Choose This Piston Seal

- Precision dimensions ensure proper fit and sealing performance

- Durable material construction withstands normal operating pressures

- Maintains flexibility and sealing characteristics during operation

- Cost-effective replacement solution for Graco 166026 applications

Typical Compatibility

- Graco pump piston assemblies

- Reciprocating pump applications

- Professional spray equipment maintenance

- Pump rebuild and service requirements

Compatible with equipment requiring Graco part number 166026.

What It Fits

- Graco airless sprayer pump piston assemblies

- Reciprocating pump systems requiring piston sealing

- Professional series equipment maintenance applications

- Pump rebuild and preventive maintenance programs

- High-pressure spray equipment service requirements

- Equipment performance restoration procedures

- Pump pressure maintenance and optimization

This Bedford 6-511 component directly replaces Graco 166026 in compatible piston sealing applications.

Technical Specifications

| Aftermarket | Bedford 6-511 |

|---|---|

| OEM | Graco 166026 |

| Component Type | Piston Seal |

| Material | Durable Sealing Compound |

| Compatibility | Graco Pump Piston Systems |

| Function | Fluid Displacement & Pressure Generation |

| Pressure Rating | Standard Pump Operation |

| Brand | Bedford Precision Parts |

Installation Notes

- Depressurize system completely before beginning disassembly

- Clean piston and cylinder surfaces thoroughly

- Lubricate seal with compatible fluid before installation

- Install without twisting or stretching the seal

- Test pump operation and check pressure performance

Pro Tip: Lubricate the piston seal thoroughly before installation and avoid stretching or twisting during placement to ensure optimal sealing performance and extended service life.

When to Replace Piston Seal

- Reduced pump pressure or performance issues

- Visible wear, cracking, or compression set

- Fluid bypass or inconsistent material delivery

- During routine pump maintenance or rebuild service

Bedford vs OEM

| Feature | Bedford Aftermarket | OEM (Graco) |

|---|---|---|

| Sealing Performance | Reliable pressure generation and fluid displacement | Factory seal specification |

| Compatibility | Direct replacement for Graco 166026 | Original equipment configuration |

| Durability | Quality material for normal operating conditions | Original material specification |

| Availability | If in stock, ships from Bedford Precision Parts in Bedford Hill, New York. | Manufacturer distribution channels |